Laser Drilling Technology- The Must of HDI PCB Boards Manufacturing

Posted: Jul 7, 2022

Categories: Blogs

Tags: PCB, PCB Fabrication, Advanced PCB, HDI PCB

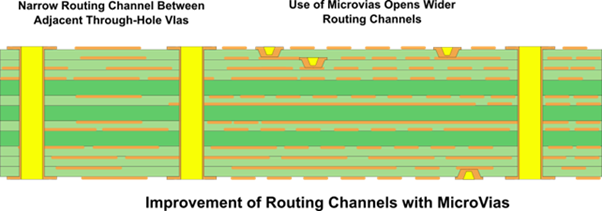

Microvias are also called blind via-holes (BVHs) in printed circuit boards (PCBs) industry. The purpose for these holes is to establish electrical connections between the layers on a multilayer circuit board. When electronics designed by HDI technology, microvias are unavoidably considered. The ability to either place on or off the pads gives the designers greater flexibility to selectively create routing space in denser parts of the substrate, consequently, the PCB boards size can be shrunk down significantly.

For PCB manufacturers of HDI boards, laser drill is the optimal choice for drilling precise microvias. These microvias are small in size and require precise controlled depth drilling. This precision can typically be achieved by lasers drills. Laser drilling is the process that uses highly concentrated laser energy for drilling (vaporizing) a hole. Laser drilling creates precise holes on a PCB board to ensure accuracy even when dealing with the smallest of sizes. Lasers can drill 2.5 to 3-mil vias on a thin flat glass reinforcement. In the case of an unreinforced dielectric (with no glass), it is possible to drill 1-mil vias using lasers. Hence, laser drilling is recommended for drilling microvias.

Although we can drill via holes of diameter 6 mil (0.15 mm) with mechanical drill bits, the tooling cost increases significantly as the thin drill-bits snap very easily, and need frequent replacement. Comparing to mechanical drilling, the advantages of lasers drilling are listed below:

- Non-contact process: Laser drilling is a completely non-contact process and therefore the damage induced on the drill bit and material by drilling vibration is eliminated.

- Precise control: The beam intensity, heat output, and duration of the laser beam are under control for laser drilling techniques, thus which helps to establish different hole shapes with high accuracy. This tolerance ±3 mil as the maximum is lower than mechanical drilling with PTH tolerance ±3 mil and NPTH tolerance of ±4 mil. This allows formation of blind, buried, and stacked vias when manufacturing HDI boards.

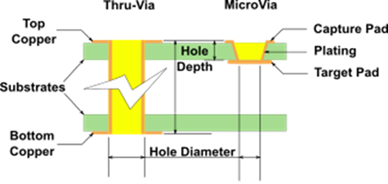

- High aspect ratio: One of the most important parameters of a drilled hole on a printed circuit board is the aspect ratio. It represents the hole depth to hole diameter of a via. Since lasers can create holes with very small diameters typically ranging from 3-6 mil (0.075mm-0.15mm), they provide a high aspect ratio. Microvia has a different profile compared to a regular via, resulting in a different aspect ratio. A typical microvia has an aspect ratio of 0.75:1.

- Cost-effective: laser drilling is significantly faster than mechanical drilling, even for drilling densely placed vias on a multilayer board. Moreover, as time passes, the extra costs from frequently replacing broken drill bits adds up and mechanical drilling can become far more expensive compared to laser drilling.

- Multi-tasking: Laser machines used for drilling can also be used for other manufacturing processes like welding, cutting, etc.

PCB manufacturers have variety options of lasers. PCB ShinTech deploys infrared and ultraviolet wavelength lasers for drilling while making HDI PCBs. Different laser combinations are necessary as PCB manufacturers use several dielectric materials like resin, reinforced prepreg, and RCC.

The beam intensity, heat output, and duration of the laser beam can be programmed under different circumstances. Low-fluence beams can drill through organic material but leaves metals undamaged. To cut through metal and glass, we use high-fluence beams. While low-fluence beams require beams of 4-14 mil (0.1-0.35 mm) diameter, high-fluence beams require beams of about 1 mil (0.02 mm) diameter.

Manufacturing team of PCB ShinTech has accumulated over 15 years expertise in laser processing and has proven track record of success in HDI PCB supply, especially in the flexible PCB fabrication. Our solutions are engineered to provide reliable circuit boards and professional service with competitive price to support your business ideas into market effectively.

Please send your inquiry or quote request to us at sales@pcbshintech.com to get connected to one of our sales representatives who have the industry experience to help you get your idea to market.

If you have any questions or need additional information, feel free to call us at +86-13430714229 or Contact Us on www.pcbshintech.com.

Post time: Jul-10-2022