HDI PCB Making ---Immersion Gold surface treatment

Posted: Jan 28, 2023

Categories: Blogs

Tags: pcb, pcba, pcb assembly, pcb manufacturing, pcb surface finish

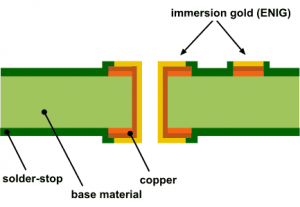

ENIG refers to Electroless Nickel / Immersion Gold, also be called chemical Ni/Au, its usage has becoming popular now due to the accountability for lead-free regulations and its suitability for the current PCB design trend of HDI and fine pitches between BGAs and SMTs.

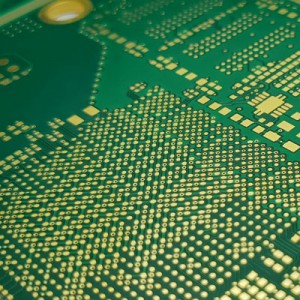

ENIG is a Chemical process which plates the exposed copper with Nickel and Gold, so it consists of a double layer of metallic coating, 0.05-0.125 µm (2-5μ inches) of immersion Gold (Au) over 3-6 µm (120-240μ inches) of electroless Nickel (Ni) as provided in the normative reference. During the process, Nickel is deposited on palladium-catalyzed copper surfaces, followed by gold adhering to the nickel-plated area by molecular exchange. The nickel coating protects the copper from oxidation and act as a surface for PCB assembly, also a barrier to prevent the copper and the gold from migrating into each other, and the very thin Au layer protects the nickel layer until the soldering process and provides low contact resistance and good wetting. This thickness remains consistent throughout the printed wiring board. The combination significantly increases the resistance to corrosion and providing an ideal surface for SMT placement.

The process includes the following steps:

1) Cleaning.

2) Micro-etching.

3) Pre-dipping.

4) Applying the activator.

5) Post-dipping.

6) Applying the electroless nickel.

7) Applying the immersion gold.

Immersion gold is typically applied after solder mask has been applied, but in a few cases, it is applied prior to the solder mask process. Obviously, this will much higher the cost if all copper is plated with gold and not just what is exposed after solder mask.

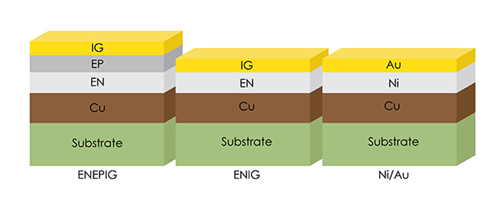

The above diagram illustrating the difference between ENIG and other gold surface finishes.

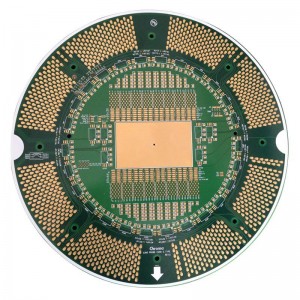

Technically, ENIG is the ideal lead-free solution for PCBs since its predominant coating planarity and homogeneity, especially for HDI PCB with VFP, SMD and BGA. ENIG is preferred in situations where tight tolerances are demanded for PCB elements like plated holes and press-fit technology. ENIG is suitable also for wire (Al) bonding soldering. ENIG is strongly recommended for boards needs involving types soldering because it’s compatible with different assembly methods such as SMT, flip chips, Through-Hole soldering, wire bonding, and press-fit technology. Electroless Ni/Au surface stands up with multiple thermal cycles and handling tarnish.

ENIG does cost more than HASL, OSP, Immersion Silver and Immersion Tin. Black pad or Black phosphorus pad happens sometimes during process where a buildup of phosphorous between the layers causes faulty connections and fractured surfaces. Another downside arising is undesirable magnetic properties.

Pros:

- Flat Surface - Excellent for Assembly of fine pitch (BGA, QFP…)

- Having excellent solderability

- Long Shelf Life (about 12 months)

- Good contact resistance

- Excellent for thick copper PCBs

- Preferable for PTH

- Good for flip chips

- Suitable for Press-fit

- Wire Bondable (When Aluminum Wire Is Used)

- Excellent electrical conductivity

- Good heat dissipation

Cons:

- Expensive

- Black phosphorus pad

- Electromagnetic interference, Significant Signal Loss at high-frequency

- Unable to Rework

- Not Suitable for Touch Contact Pads

Most common uses:

- Complex surface components such as Ball Grid Arrays (BGAs), Quad Flat Packages (QFPs).

- PCBs with Mixed Package Technologies, press-fit, PTH, wire bonding.

- PCBs with wire bonding.

- High reliability applications, for example PCBs in industries where precision and durability are vital, such as aerospace, military, medical and high-end consumers.

As a lead PCB and PCBA solutions provider with more than 15 years’ experience, PCB ShinTech is capable to provide all kinds of PCB board fabrication with variable surface finish. We can work with you to develop ENIG, HASL, OSP and others circuit boards customized to your specific requirements. We feature competitively priced PCBs of metal core/aluminum and rigid, flexible, rigid-flexible, and with standard FR-4 material, high TG or other materials.

Back to Blogs

Post time: Jan-28-2023