HDI PCB making in an automated PCB factory --- ENEPIG PCB surface finish

Posted: Feb 03, 2023

Categories: Blogs

Tags: pcb, pcba, pcb assembly, pcb manufacturing, pcb surface finish, HDI

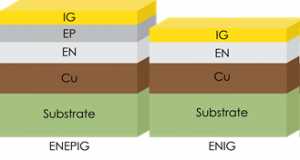

ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) is not a commonly-used PCB surface finish at present while has become increasingly popular in PCB manufacturing industry. It is applicable for a wide range of application e.g., varied surface packages and highly advanced PCB boards. ENEPIG is an updated version of ENIG, with the addition of a Palladium layer (0.1-0.5 µm/4 to 20 μ'') between Nickel (3-6 µm/120 – 240 μ'') and Gold (0,02-0,05 µm/1 to 2 μ'') through an immersion chemical process in PCB factory. The palladium acts as a barrier to protect the nickel layer from corrosion by Au, which helps prevent “black pad” from occurring which is a big issue for ENIG.

If no bonding of budget, ENEPIG seems a better option on most of conditions especially of ultra-demanding requirements with multiple package types like, through-holes, SMT, BGA, wire bonding, and press fit, when comparing to ENIG.

Moreover, Excellent durability and resistance make it long shelf life. Thin immersion coat makes parts placement and soldering easy and reliable. In addition, ENEPIG provides a high reliable Wire Bonding option.

Pros:

• Easy to process

• Black Pad Free

• Flat surface

• Excellent shelf life (12 months+)

• Allowing multiple reflow cycles

• Great for Plated Through Holes

• Great for Fine Pitch / BGA / Small Components

• Good for Touch Contact / Push Contact

• Higher Reliability Wire Bonding (gold/aluminum) than ENIG

• Stronger Solder Reliability than ENIG; Forms reliable Ni/Sn solder joints

• Highly compatible with Sn-Ag-Cu solders

• Easier Inspections

Cons:

• Not all manufacturers can provide it.

• Wet required for longer duration.

• Higher cost

• The efficiency is affected by plating conditions

• May not be as reliable for gold wire bonding when compared to Soft Gold

Most common uses:

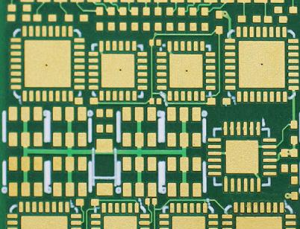

High Density Assemblies, Complex or Mixed Package Technologies, High Performance Devices, Wire Bonding application, IC carrier PCBs, etc.

Back to Blogs

Post time: Feb-02-2023