How to Choose Surface Finish for Your PCB Design

---An Expert’s Guide to PCB Surface Finishes

Ⅰ What and How

Posted: Nov 15, 2022

Categories: Blogs

Tags: pcb, pcba, pcb assembly, pcb manufacturer, pcb fabrication

When it comes to surface finishes, there are various options, e.g. HASL, OSP, ENIG, ENEPIG, Hard Gold, ISn, IAg, etc. In some cases, it may be easy to make the decision, such as edge connection goes to hard gold; HASL or HASL-free is preferable for larger SMT components placement. However, it may be tricky to choose one finish for you HDI boards with Ball Grid Arrays (BGAs) if there is no other clues. There are factors such as your budget for this project, requirements for reliability or the constrains for operation time need to be considered on some conditions. Each type of PCB surface finish has its pros and cons, it may be confusing for PCB designers to decide which one is suitable for your PCB boards. We are here to help you figure them out with our many years’ experience as a manufacturer.

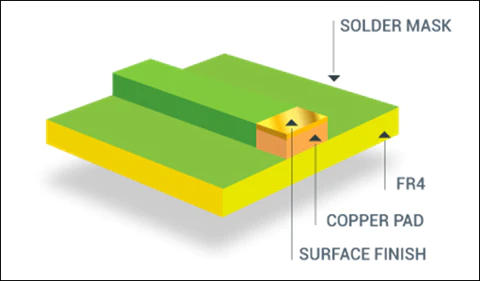

1. What is PCB surface finish

Applying the surface finish (surface treatment / surface coating) is one of the last steps of fabricating PCBs. The surface finish forms a crucial interface between a bare PCB board and components, servicing for two essential purposes, to provide a solderable surface for PCB assembly and to protect the remaining exposed copper including traces, pads, holes and ground planes from oxidation or contamination, while the solder mask covers the majority of the circuitry.

Modern surface finishes are lead-free, in accordance with Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives. Modern PCB surface finish options include:

- ● LF-HASL (Lead Free Hot Air Solder Leveling)

- ● OSP (Organic Solderability Preservatives)

- ● ENIG (Electroless Nickel Immersion Gold)

- ● ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold)

- ● Electrolytic Nickel/Gold - Ni/Au (Hard/Soft Gold)

- ● Immersion Silver, IAg

- ● White Tin or Immersion Tin, ISn

2. How to choose surface finish for your PCB

Each type of PCB surface finish has its pros and cons, it may be confusing for PCB designers to decide which one is suitable for your PCB boards. Choosing the correct one for your design requires taking multiple factors into account as the following.

- ★ Budge

- ★ The circuit boards final application environment (for example temperature, vibration, RF).

- ★ Requirements for Lead free applicant, environmental friendly.

- ★ Reliability requirement for the PCB board.

- ★ Components type, density or requirements for assembly e.g. press fit, SMT, wire bonding, Through-hole soldering, etc..

- ★ Requirements for surface flatness of SMT pads for BGA application.

- ★ Requirements for Shelf life and reworkability of surface finish.

- ★ Shock/drop resistance. For example, ENIG is not suitable for smart phone since smart phone requires tin-copper bonds for high shock and drop resistance instead of tin-nickel bonds.

- ★ Quantity and Throughput. For a high volume of PCBs, immersion tin can be a more reliable and cost-effective options than ENIG and Immersion Silver and tarnish sensitivity issues can be avoided. On the contrary, immersion silver is better than ISn at a small batch.

- ★ Susceptibility to corrosion or contamination. For example, immersion silver finish is prone to creep corrosion. Both OSP and Immersion tin are sensitive to handling damage.

- ★ Aesthetics of the board, etc..

Back to Blogs

Post time: Nov-15-2022